ASME Section VIII⁚ An Overview

The ASME Boiler and Pressure Vessel Code (BPVC) Section VIII details rules for constructing pressure vessels. It’s divided into three divisions, each addressing specific design and construction aspects. Division 1 covers standard pressure vessels, while Divisions 2 and 3 handle alternative rules and high-pressure vessels respectively. The code ensures safe operation and addresses materials, fabrication, inspection, and testing.

The ASME Boiler and Pressure Vessel Code (BPVC) is a widely recognized international standard for the design, fabrication, and inspection of boilers and pressure vessels. Established to enhance safety after numerous historical explosions, it’s a crucial resource for engineers and manufacturers worldwide. The code’s comprehensive guidelines cover various aspects, from material selection and welding procedures to non-destructive examination and certification. Its purpose is to define minimum requirements for safe operation, thereby preventing catastrophic failures. The BPVC is regularly updated to incorporate advancements in technology and materials science, ensuring its continued relevance in a constantly evolving industrial landscape. Compliance with the BPVC is often a legal requirement in many jurisdictions, emphasizing its importance in ensuring public safety and industrial reliability. The code’s detailed provisions address a broad range of pressure vessel applications across diverse industries, from small compressed air receivers to large-scale petrochemical equipment.

Section VIII⁚ Rules for Construction of Pressure Vessels

ASME Section VIII, a pivotal part of the BPVC, specifically addresses the construction of pressure vessels. It provides detailed requirements for design, fabrication, inspection, testing, and certification, ensuring safe operation across diverse applications. This section is not merely a collection of guidelines; it’s a comprehensive framework ensuring the integrity of pressure vessels operating under internal or external pressure. The rules within Section VIII are meticulously crafted based on extensive research, engineering principles, and industry best practices, minimizing the risk of failures. The code’s stipulations extend to various materials, welding methods, non-destructive testing techniques, and pressure relief device specifications. The goal is to provide a robust set of rules that can be applied consistently across various industrial contexts, promoting uniformity and enhancing safety standards. Adherence to Section VIII is vital for ensuring the long-term reliability and safety of pressure vessels, protecting both personnel and equipment. It serves as a cornerstone of responsible engineering practice in the design and manufacturing of pressure vessels for various industries.

ASME Section VIII Division 1

This division establishes mandatory requirements and guidance for pressure vessel design, fabrication, inspection, testing, and certification. It covers a wide range of applications, from small compressed air receivers to large industrial vessels. Compliance ensures safe operation.

Design, Fabrication, Inspection, and Testing Requirements

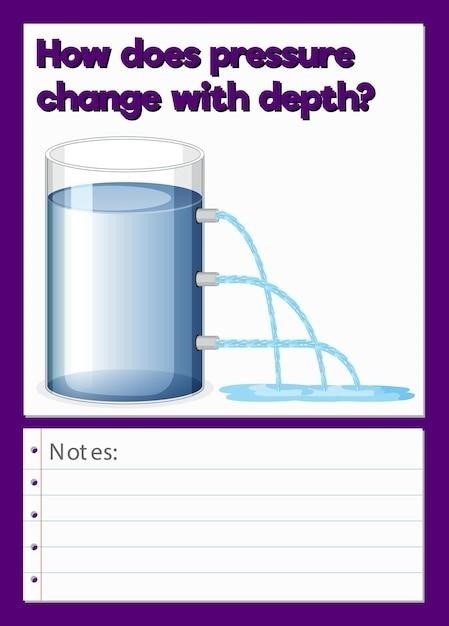

ASME Section VIII Division 1 meticulously outlines the design criteria for pressure vessels, encompassing crucial aspects like material selection, allowable stresses, and geometric considerations. These specifications are vital for ensuring structural integrity and preventing catastrophic failures. Fabrication procedures are strictly regulated, covering welding techniques, joint design, and quality control measures to guarantee the vessel’s structural soundness. Rigorous inspection protocols are mandated throughout the manufacturing process, from raw material evaluation to non-destructive testing methods like radiography and ultrasonic examination. These inspections aim to detect any flaws or imperfections that could compromise safety. Finally, comprehensive testing procedures, often involving hydrostatic or pneumatic pressure testing, verify the vessel’s ability to withstand operational pressures safely. Adherence to these requirements is paramount for achieving the code’s objectives of safety and reliability.

Materials and Welding Guidelines in Division 1

ASME Section VIII Division 1 provides comprehensive guidelines on acceptable materials for pressure vessel construction. These guidelines specify material properties, including tensile strength, yield strength, and ductility, ensuring suitability for the intended service conditions. The code lists approved materials, often referencing specific material specifications from organizations like ASTM International. Welding procedures are rigorously defined, encompassing welder qualification, welding processes, and post-weld heat treatment. The selection of welding processes depends on factors such as material thickness and joint configuration. Strict quality control measures are implemented to ensure the integrity of welds, including visual inspection, radiographic examination, and other non-destructive testing methods. These stringent requirements aim to prevent weld defects that could compromise the pressure vessel’s structural integrity and safety during operation. The code also addresses the use of filler metals, ensuring compatibility with the base materials to maintain weld quality and prevent corrosion.

ASME Certification Marks and Their Significance

ASME certification marks, prominently displayed on compliant pressure vessels, signify adherence to the rigorous standards outlined in the ASME Boiler and Pressure Vessel Code, Section VIII. These marks provide assurance to users that the vessel has undergone comprehensive design, fabrication, inspection, and testing procedures, conforming to the code’s requirements. The presence of an ASME certification mark indicates that the manufacturer has demonstrated compliance through rigorous quality control measures and undergone audits to verify their processes. Different marks may be present, depending on the specific division of Section VIII (Division 1, 2, or 3) under which the vessel was designed and constructed, indicating the scope of the code’s application. The certification mark provides a critical level of safety assurance, offering confidence in the vessel’s ability to withstand operational pressures and preventing catastrophic failures. It serves as a visual guarantee of quality and a testament to the manufacturer’s commitment to safety standards.

ASME Section VIII Division 2

This division offers alternative rules for pressure vessel construction, providing flexibility beyond Division 1’s mandatory requirements. It’s often chosen for specific applications needing design optimization or specialized materials.

Alternative Rules for Pressure Vessel Construction

ASME Section VIII Division 2 presents alternative rules, diverging from Division 1’s prescriptive approach. This allows for more flexibility in design and construction, particularly beneficial for complex or specialized pressure vessels. Division 2 emphasizes performance-based design, focusing on demonstrating compliance through analysis rather than strict adherence to specific rules. This approach necessitates a deeper understanding of stress analysis, material behavior, and failure mechanisms. Designers utilize advanced computational techniques and rigorous testing to validate the safety and integrity of the vessel, often leading to optimized designs that may be lighter, more efficient, or better suited to unique operational conditions. The use of Division 2 requires experienced engineers proficient in advanced analysis methods and a thorough understanding of the underlying principles of pressure vessel design. While this approach offers design freedom, it also increases the responsibility on the designer to justify the chosen design parameters and ensure compliance with safety standards. The increased complexity might translate to higher upfront engineering costs, but potential long-term benefits like improved efficiency and reduced material usage can offset these initial investments. The shift from prescriptive rules to performance-based criteria necessitates detailed documentation and justification for every design choice.

ASME Section VIII Division 3

This division addresses high-pressure vessel design and construction, exceeding 10,000 psi. It establishes no maximum pressure limits, offering rules for single ASME certification marks with UV3 and U3 designators. Detailed requirements ensure safe operation at extreme pressures.

High-Pressure Vessel Design and Construction

ASME Section VIII Division 3 delves into the intricacies of high-pressure vessel design and construction, focusing on vessels operating at pressures exceeding 10,000 psi. Unlike Divisions 1 and 2, Division 3 does not impose a maximum pressure limit, making it suitable for a wide range of exceptionally high-pressure applications. The design rules within this division are specifically tailored to handle the unique challenges posed by extreme pressures, incorporating advanced materials, sophisticated fabrication techniques, and rigorous testing protocols; This ensures the utmost safety and reliability for these critical pressure vessels. The detailed guidelines help engineers and fabricators to address stress concentrations, material selection for extreme conditions, and the implementation of specialized welding and inspection procedures. Moreover, Division 3 provides comprehensive guidance on the use of the single ASME certification mark, specifically addressing its application to UV3 and U3 designators. This aspect of the code reinforces the traceability and quality assurance integral to high-pressure vessel fabrication.